Mechanical Engineering books

Reviewed by: T.J. Nelson

These mechanical engineering textbooks are great autumn reading while lying under your car.

Standard Handbook of Machine Design, 3rd ed.

by Shigley, Mischke, and Brown

higley, as this book is known, is a well-known reference text for

mechanical engineers. This book is not for beginning engineering

students. It seems to be aimed at professional engineers who already

understand the basic principles. The writing in Shigley is a model of

conciseness. Occasionally, this conciseness is carried too far: explanations

of the origin or the implications of the formulas are not provided, and

important topics are sometimes missing from the index. For example,

in the section on gears the important concept of involute profile of a gear

is referred to in passing but never defined, and it's missing from the index.

Gear concepts are explained more clearly in Gears and Gear Cutting

by Ivan Law.

higley, as this book is known, is a well-known reference text for

mechanical engineers. This book is not for beginning engineering

students. It seems to be aimed at professional engineers who already

understand the basic principles. The writing in Shigley is a model of

conciseness. Occasionally, this conciseness is carried too far: explanations

of the origin or the implications of the formulas are not provided, and

important topics are sometimes missing from the index. For example,

in the section on gears the important concept of involute profile of a gear

is referred to in passing but never defined, and it's missing from the index.

Gear concepts are explained more clearly in Gears and Gear Cutting

by Ivan Law.

Shigley also contains numerous formulas. In fact, some pages consist entirely of equations. The equations are all simple algebra--very little calculus or advanced math of any kind. Those coming from a science background will be surprised to find that few equations are actually derived in the text. In most sections, the formula is simply presented as a fact, with appropriate constants. This makes sense in engineering, because many of the equations are simply empirical relationships that were measured for a specific situation. Nonetheless, they are actually quite useful. One formula, for example, gives the temperature of a heated object as a function of the velocity of the airflow around it. It may not be as accurate as the ones used by physicists, but with the appropriate fudge factors--I mean, empirical constants--it's a lot more convenient.

This doesn't mean the treatment is not abstract; in fact, the reader needs strong ability to visualize three-dimensional objects to make sense of what the authors are saying. There's also little discussion of how the object is made, or of the basic principles behind its operation--the theory of friction, for example, is not discussed. In some ways, this is a disadvantage, because it's important for engineers to know how, or whether, something could be economically manufactured while they're designing it. However, adding background information would probably have doubled the size of this book, which is already 2¼ inches thick.

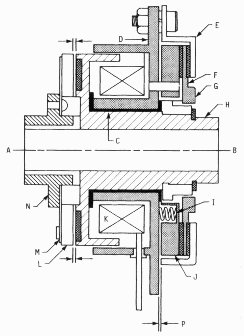

There are also numerous tables and engineering diagrams. For example, the image above is Fig. 8.28 showing a clutch-brake transmission. To those not accustomed to reading these diagrams, it might take a while to figure out how this particular device works, but to an engineer it would be clear.

The coverage of mechanical engineering topics is impressively complete. The section on springs includes constant-force springs. The section on brakes includes a paragraph on dynamic braking (although it doesn't mention that dynamic braking is a DC phenomenon). Even basic stuff like screws and rivets merit their own chapter. These chapters are packed with useful information, like the fact that a variation of only two degrees away from vertical can reduce the fatigue life of a bolt through a hole to only 25% of normal. Considerable attention is also paid to failure analysis, vibration, and stress. These later sections contain many graphs and equations.

Sep 27, 2010

Parts Fabrication: Principles and Process

The Handbook of Manufacturing Engineering, 2nd ed

Richard Crowson, ed.

ccording to the Preface, the purpose of this book is to equip executives and

others who know absolutely nothing about how to do anything to talk to those who

do without sounding like morons. (The author doesn't phrase it exactly this way,

but that's the gist of it.) After all, the boss needs to be able to talk about

whatever the company is making without the engineers snickering behind their

back. In a sense, this book is Manufacturing Engineering for Dummies

without the cartoons.

ccording to the Preface, the purpose of this book is to equip executives and

others who know absolutely nothing about how to do anything to talk to those who

do without sounding like morons. (The author doesn't phrase it exactly this way,

but that's the gist of it.) After all, the boss needs to be able to talk about

whatever the company is making without the engineers snickering behind their

back. In a sense, this book is Manufacturing Engineering for Dummies

without the cartoons.

That said, this book succeeds adequately as a gentle introduction to basic materials engineering. Concepts are explained with concrete examples, and provide an intuitive understanding. However, the treatment is superficial. Only the most basic math is used. There are brief chapters on metallurgy, machining, non-traditional machining (such as EDM), composites, and finishing. If you're an engineer or technically-oriented person, you probably won't learn much. If not, I recommend reading this book before, not after, reading Shigley (reviewed at left).

Dec 27, 2010